| Mold Shields

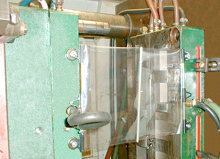

Mold Shields prevent your parts from scattering randomly within the mold’s open space by keeping them within the desired "drop zone". Mold Shields are a crystal clear plastic curtain which attaches to either side of the mold using magnets. As the mold opens and closes, the Mold Shields expand and contract to provide a curtain that prevents molded parts from falling outside the drop zone.

The crystal clear plastic allows you to observe your molding area, and monitor your parts production in progress. With an in-service life expectancy of 3 million cycles, Mold Shields have a rapid pay back based on scrap reduction and increased good production output. Since Mold Shields are easily attached and removed as necessary, they can be quickly moved from press to press to meet changing production demands or simply removed in seconds for equipment maintenance purposes. Mold Shields are easy to install and remove, with some assembly of hardware required. For larger applications, multiple Shields can be used on a mold.

Features:

- Sizes range from 12" to 24" height x 24" width

- Includes mounting hardware and magnets

- Temperature ranges from 0° to 230° F

- Reduces scrap

- Eliminates contamination

- Easy installation

- Quick access to mold

- Movable to other presses

|

|

| Mold Chutes

Mold Chutes are an ideal solution to prevent your parts from scattering randomly in the "drop zone." Mold Chutes ensure your parts land on the conveyor or in the packing case -- not on the floor.

Mold Chutes are made of durable plastic with a PVC lining in the bottom to protect even delicate molded parts. They are uniquely constructed so they will not absorb oil or grease, while being abrasion, puncture and tear resistant. They are easy to clean and have no folds to trap moldings or dirt. Mold Chutes are available in a wide variety of styles and sizes, and can easily be attached to your machine using magnets. |

|

![]()